SVG Sit-Down: NEP Broadcast Services Global President Mike Werteen on a Connected Production Future

The key message at IBC 2022 was ‘people and innovation’

Story Highlights

NEP Group’s evolution was on display at IBC 2022 with representatives from around the world onsite to meet with clients and discuss future planning as well as innovations like the NEP TFC Flow System and the buildout of connected data centers, production facilities, and new trucks. During the show, SVG sat down with Mike Werteen, global president, NEP Broadcasting Services, NEP Group, to discuss all the developments and more.

NEP Group’s Mike Werteen: “This is an exciting time. We’re able to give our clients more options in how they want to produce their stories.”

NEP Group has changed a lot since the last IBC. What are some of the key messages this year?

It’s all about people and innovation. For example, since the last IBC show, we’ve added a lot of great people to NEP, but, due to the pandemic in some cases, we’ve met only through Teams or Zoom. For instance, we acquired a broadcast-services company called HDR in Sweden in November 2019, and, while it has been a great collaboration, now we can all meet clients, vendors, and, importantly, each other in person. And that has been worth its weight in gold.

Has it also become more complicated?

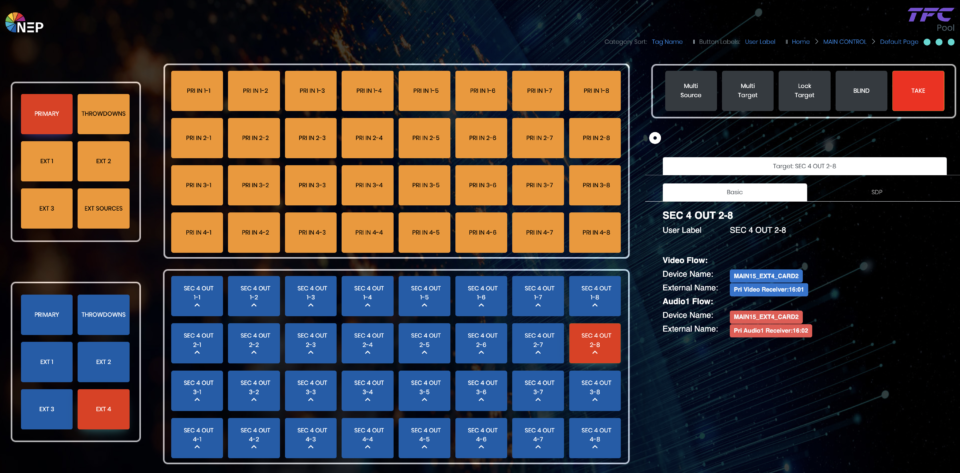

That’s where the innovation comes in. We spent time during the pandemic developing a number of new products that we think are real game-changers, like our IP-based NEP TFC Flow system, which, by the way, won Best in Show at IBC. TFC Flow combines the intuitive app of TFC (total facility control) with scalable nodes (hardware) across a network to manage the signal flow of data, intercom, video, and audio feeds in the field. It massively increases flexibility while speeding up and simplifying what was previously a very time-consuming complex setup. It’s a great example of an NEP software solution paired with hardware to create a more efficient solution for our clients. Software streamlines the setup, but there is still a significant need for hardware in our industry. We want to make sure we’re doing our part to keep our clients satisfied and our vendors healthy, as we’re a large purchaser and integrator of gear.

NEP Group’s TFC Flow allows a high level of control of data, communications, video, and audio signals between remote facilities.

And it’s not just about what’s coming next: it’s about what we need to do now, as the future is already here. We’re still building out mobile units, and we’re going to have the largest number of mobile-unit builds in 2023, but they’re now all IP-based with TFC fully integrated. We’re also leaning into centralized production, and a lot of our clients have come on board and agree with the vision we have for remote production. We have a platform and a ring of connectivity in regions, but our ambitions are to extend that globally.

You mention the truck builds. What’s the future of trucks? Are you surprised to be building so many? And will they be less hardware-intensive?

What has been surprising to me is, the mobile units that have not been tied to a specific client have been in high demand. That tells me there’s still a need for those solutions, albeit with more connectivity and control. That said, our clients have demanded that there needs to be a roadmap to the next step. We believe in centralized production, and, when you have the control layer we have — NEP’s TFC — and you incorporate that into new builds, it can help the design of individual shows and tie together large compounds with our data centers. TFC has also enabled us to build an overall platform that will be a launch point for all kinds of software-based tools and products. But more to come on that soon.

The new data center in Dallas opens within a couple of months. Where does that stand?

It’s going to be launched in the fourth quarter, and we already have the racks in the space; now we’re putting in the gear. We went through a long search to find the right location for it, but it won’t be our only one. It will also be connected to our facilities in New York and Los Angeles as well as to the NASCAR Production Center in Charlotte, NC. Other clients will be connected to the ring and will be able to use the resources. In some cases, it will be true remote production; in others, it will include components of the production. Every one of the conversations with clients is a little bit different, but we want to make sure we can accommodate those needs. So far, we haven’t run into anything we can’t accommodate.

The beauty of a data center is how it allows you to get much more utilization out of gear, because gear in a truck driving from point A to point B isn’t being used. How does this improve the economics and return on investment?

It definitely improves investment analysis when we get to a critical mass of clients on the network, which is important when you think of what has happened with inflation, people, and supply-chain constraints over the last few years. When you think back, the whole mobile-unit industry started with the outsourcing of resources because the networks couldn’t make the business case based on the utilization that they had for their own events. It became advantageous for everyone because the equipment would be used for the primary work as well as additional contractual work. And the same gear, switcher, cameras, audio consoles, replay servers, and graphics benefited from that additional utilization.

We’re taking that model and expanding it. What we’re doing for centralized production supercharges everything. Built into the economics were things like drive times, but it was still inefficient because, when equipment is on the road, there’s no way for it make money and reduce prices for everybody. It’s our view that greater utilization can be found by connecting everything around the world. When resources in one area aren’t used because people are asleep or there is no event going on, we can now use those resources. We’ve been doing this for years in some major regions around the world, so we have real-world experience. Now we’re expanding to the U.S. and connecting it all globally. There are people within NEP Group who are a lot smarter than I am who say this is achievable.

You have NASCAR signed up to use the Dallas data center with its production-control rooms elsewhere. What is the potential for how that can change things like where facilities like studios are located?

Once we have the connected network, there is the potential to have smaller footprints where the client wants them from a business standpoint, and that could even be corporate headquarters or a studio with an iconic view in the background. All of that opens up, as you don’t need to build large facilities because you’re pulling resources from a central location.

How do you get clients to buy into the concept?

The reality is, we thought we’d be a few years ahead of the global demand, but clients are proactively coming to us at an incredible pace. We think it’s a combination of their successful experiences during the pandemic, as well as the tightening economic environment, where flexibility and efficiency are even more important. Plus, they have confidence in NEP because we have multiple years of experience doing this in some of our locations: Australia and the Netherlands have been test beds, and they’ve succeeded. So we feel there is credibility to saying this is a reliable and cost-effective solution. Also, many of our clients have committed to sustainability and reducing their carbon footprint, and NEP has, too. Centralized production will help us make a positive impact on that initiative because we’re moving less equipment and people.

How do you think this will impact truck design?

Firstly, the move to IP accelerates, as well as our integration of TFC across our facilities globally. Then there are the trucks themselves. We’re building a lighter version of our trucks because we don’t need as much equipment or people in the field. Those conversations are different for different clients depending on the workflow and what redundancy might be needed onsite. But, the way things have gone so far, there is less gear onsite as backup because everything has been reliable enough that it isn’t needed.

But, yes, there is going to be an evolution of mobile units to something that is less dense than in the past. However, for the clients that require a large onsite presence for tent-pole events, we’re building those out. So there’s two sides to it.

I think this is an exciting time. We’re able to give our clients more options in how they want to produce their stories. The educational process is part of it and something that we’re spending a lot of time on both internally and with our clients. The business we’ve been in for decades is changing, but I feel good about the position NEP is in.

What are your thoughts on some of the general economic challenges — inflation, supply-chain issues — that are impacting every industry?

Inflation has truly impacted us, and that can include materials, energy, or even the cost of the supply chain. We’ve done some analysis on it, and our costs have gone up, depending on the geography, 12%-20% from where they were previously. There are discussions that will need to be had with our clients so that we can all have sustainable businesses. We’ve never seen inflation like this before. Some of the assumptions we’ve made in the past have to be thrown out the window since we often went by precedent as to what the costs of business would be. We need to have some conversations that we’ve never had before in a helpful, pragmatic, and honest way. It comes down to understanding we are all in this together. The good news is, the pace and speed of innovation has never been greater, and that provides an opportunity for new, more-flexible, and more-efficient solutions for those willing to lean in.