OB-Truck Suppliers Target Energy-Efficiency in Enhancing Sustainability

Reduced footprint, merged technologies, and renewable fuels are part of the effort

Story Highlights

Inherently resource-intensive processes frequently pose challenges for live productions striving to align with sustainability metrics. The dynamic nature of production often leads to reliance on traditional, less eco-friendly practices. OB-truck providers are considering ways to make their vehicles more sustainable.

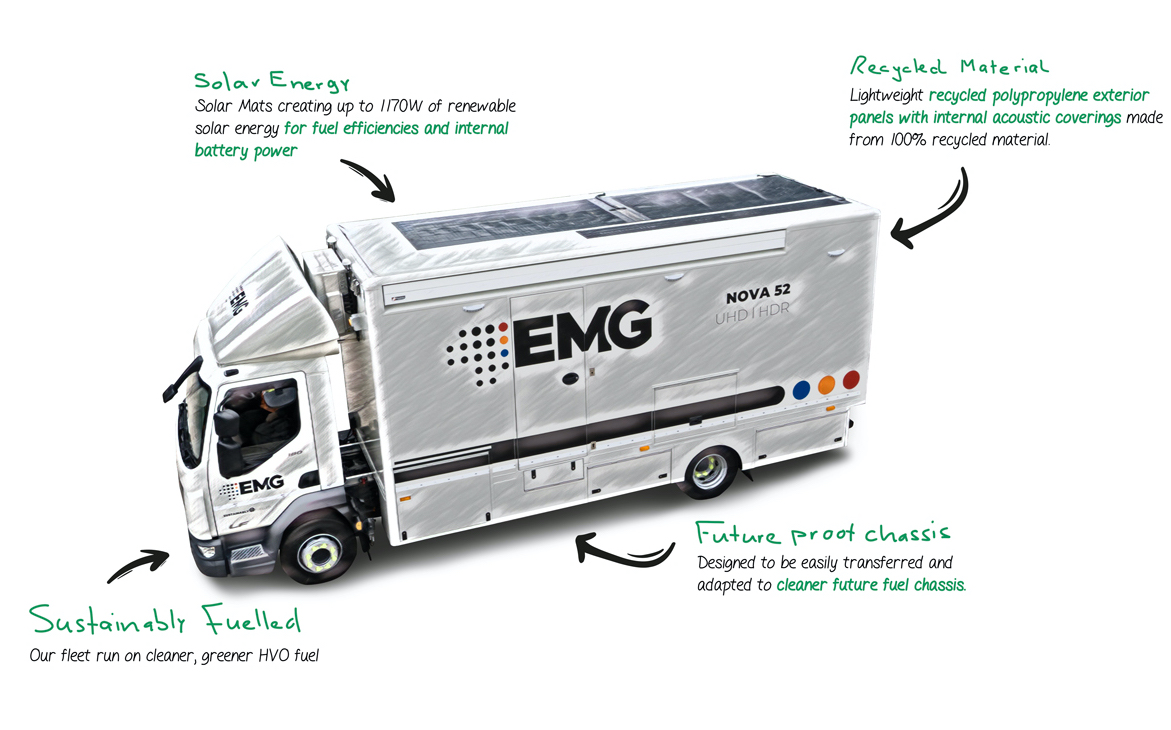

Forward-looking suppliers champion sustainability by considering all aspects of the truck to gain energy-efficiencies. Their efforts entail delivering technology within a smaller footprint, merging technologies, and using renewable fuels, such as hydrotreated vegetable oil (HVO), for both the truck and backup generators.

Broadcast-services provider EMG Gravity Media has tackled power-efficiency. “EMG’s latest development, the Nova 50 series remote-production vehicle, has been designed to accommodate all styles of production, from traditional to cloud-based,” explains EMG Gravity Media Group Director, ESG, Rohan Mitchell, who spearheads environmental, social, and governance initiatives ensuring that the company operates ethically, sustainably, and responsibly. “Every piece of equipment in these new vehicles has been considered for its power efficiency, weight, and size. This design integrates low-power-hungry technology along with hyperconverged equipment, resulting in a compact form factor, flexible workflows, and more-efficient use of power.”

Power-related issues can impact the reliability, efficiency, and overall quality of a live broadcast. The power needs of an OB truck can vary significantly based on the scale and complexity of the production. The ability to adapt to these dynamic requirements is crucial, requiring not only a reliable power supply but also backup and redundancy systems. Backup systems often take the form of battery or generators, each contributing its share of sustainability challenges. For example, lithium batteries with their rare-earth metals are being replaced with batteries using innovative alternatives based on sodium chloride.

A significant industry challenge lies in the general lack of knowledge regarding sustainable choices without compromising quality. For instance, understanding the actual energy consumption of OB trucks compared with remote-production alternatives remains elusive, given the unique setup of each production. Collaborative efforts within the industry should focus on collecting accurate data and benchmarking the true energy costs associated with various production setups, as well as upskilling teams on best practices in sustainable quality productions. Equipping OB-truck providers and broadcasters with knowledge about sustainable options empowers them to make informed production choices.

Says Mitchell, “When aligning with your own ESG [environmental, social, and governance] program, OB vehicles can fulfill a host of sustainability goals, including energy efficiency and reduced onsite-staff requirements, while providing a state-of-the-art technology infrastructure for quality productions.”

Note: The views expressed here are solely those of the author and/or interview subject and do not represent positions of SVG.